MOVE

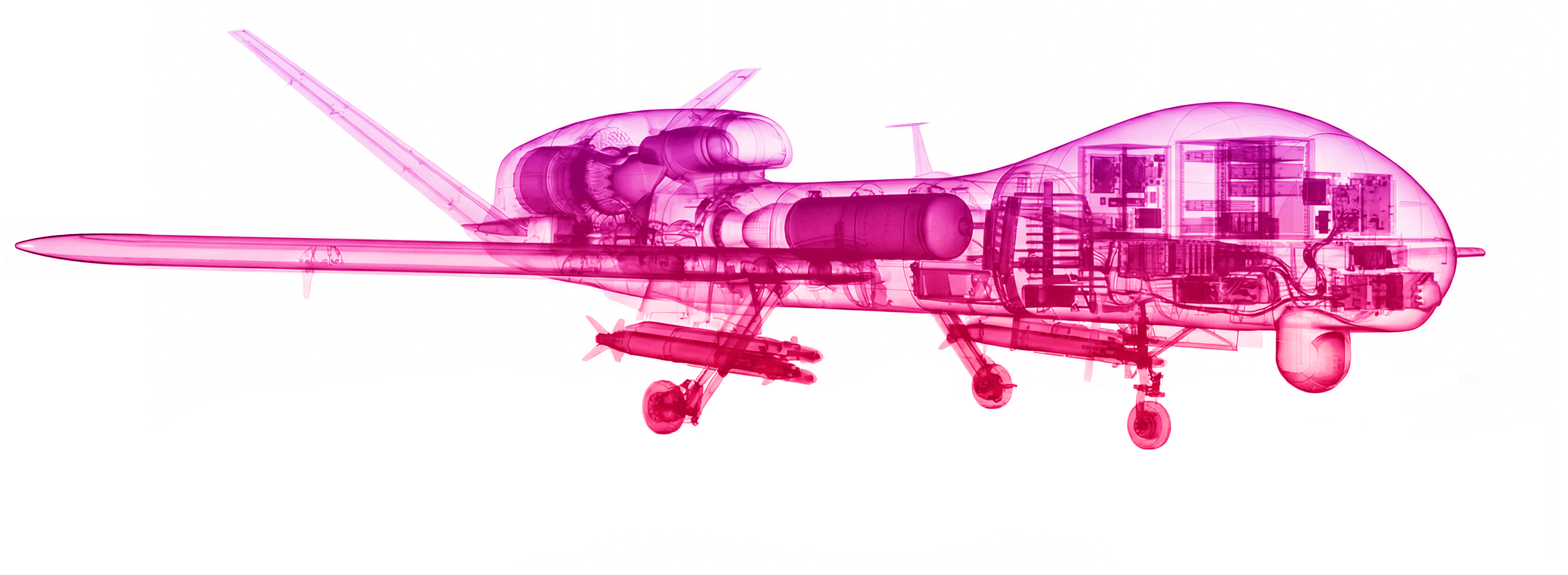

Resupply and Distribution Optimization

Plan and optimize military supply flows through complex multi-modal networks while operating in contested environments vulnerable to interdiction.

Understanding the Problem

Military resupply and distribution involves optimizing supply flows across sea, land, air, and rail transportation spanning multiple geographic regions. Modern logistics must balance speed, cost, security, and resilience while operating where supply lines face drones, long-range munitions, and enemy intelligence. Traditional assumptions of safe rear-area logistics no longer hold. Distribution centers and transport routes must be dispersed, mobile, and timed to minimize detection. Russia's logistics failures in Ukraine demonstrated how supply problems can halt offensive operations.

THE CHALLENGE

What Makes it Hard

Military planners must route supplies through contested environments where convoys face attack, while coordinating across multiple transportation modes, managing unpredictable combat-driven demand, and integrating data across services and allies.

WHO FACES IT

Multi-modal networks integrate sea, land, air, and rail with varying infrastructure capabilities and capacity constraints

Supply convoys face drone attacks, artillery fire, and enemy surveillance requiring concealment and survivability optimization

Combat operations create unpredictable demand spikes, equipment failures, and evolving mission requirements

BUSINESS IMPACT

Optimization achieves 75% maintenance prediction accuracy, 20% improved packing efficiency, and 12% mission cost savings with up to 50% fewer required aircraft.

Get critical supplies where they need to be, even under adversarial conditions.

Predictive Maintenance

75%

Accuracy[1]

ML systems achieve 75% accuracy in predicting unplanned maintenance work for military aircraft, enabling proactive scheduling.

Packing Efficiency

20%

Improvement[2]

UK MoD's LOGOS system increased military packing efficiency by 20% while reducing planning time from hours to seconds.

Mission Cost Savings

12%

Reduction[3]

AWS air logistics optimization demonstrated 12% mission operation cost savings and up to 50% reduction in required aircraft.

How We Solve It

Multi-objective vehicle routing with time windows (VRPTW), capacity constraints, and network interdiction considerations. Core formulation is mixed-integer programming combining routing decisions, fleet assignment, and scheduling. Objective function includes concealment measures and security metrics alongside traditional cost/time optimization.

Hybrid Compute

What We Bring

Route optimization through contested transportation networks

Fleet assignment across multiple vehicle types and modes

Security-aware scheduling to minimize detection exposure

Rapid replanning as battlefield conditions change

FUTURE POSSIBILITIES

The

Quantum Horizon

QAOA has solved VRP with up to 13 locations using multi-angle approaches. Hybrid methods achieve 2-4% optimality gaps on 50-location CVRP. D-Wave systems solve QUBO-formulated VRP variants with time and capacity constraints for small instances.

Exploratory Work

Quantum-inspired algorithms running on classical hardware deliver 10-20x speedups and are the most practical near-term approach. Direct quantum solutions limited to small subproblems (<7 customers). Classical solvers remain superior for strategic network optimization.

Current Research Directions

Hybrid quantum-classical approaches for capacitated VRP benchmarks

Quantum annealing for automated guided vehicle routing in depots

Quantum-inspired algorithms achieving 15% cost reductions on route optimization

Interested in quantum research?

Explore proof-of-concept implementations with our team.

Where this applies

Ready to solve this problem?

Talk to our experts about how Strangeworks can help with resupply and distribution optimization.